Fuel oil burner: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

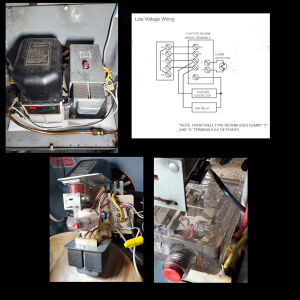

The '''fuel oil burner for my home furnace system'''. | [[File:Furnace control system.jpg|thumb|Composite image, photos of control system for fuel oil boiler.]]The '''fuel oil burner for my home furnace system'''. | ||

== History == | == History == | ||

Revision as of 12:03, 27 October 2020

The fuel oil burner for my home furnace system.

History

It fired up for me twice in two days. Ran heat for less than two hours each time, then shut down.

Both times I bled the lines. Fuel flowed freely, no sign of water.

I have not inspected the filter; should do so, but I expect it is okay, as fuel flows freely.

I opened up the oil burner cover, inspected the UV sensor, found it faintly cloudy (but not sooty). Swabbed sensor with isopropyl alcohol, closed cover. No go.

Problem state

Primary control appears to be locked out or failing.

Holding red button for extended period of time (30 seconds, 60 seconds) does not clear the lockout.

Diagnosis:

- Hardware is good, control unit is in locked state, unlock procedure needed

- Control unit is bad, needs repair

- Oil pump bad, needs repair

I think the oil pump (3) is least likely. The control system is the problem.

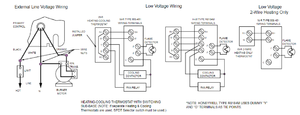

The controller also controls the cooling unit, making sure that when the furnace is running the cooling unit is locked out, and vice versa.

Oil burner

Beckett.

Primary control

White-Rodgers 668-451 Kwik-Sensor Cad Cell Relay Oil Burner Control 2-Wire 45-Second Timer & External Transformer

This is a "stack relay" device — an older technology.

Specifications

ELECTRICAL DATA

Input voltage: 120 VAC, 60Hz.

Maximum Load Current:

Oil Burner Motor (Orange Wire): 10 Amps F.L. 60 Amps L.R.

Ignition Transformer: 360VA (3.0 Amps)

Relay Voltage: 24 Volts AC, 60Hz.

Room Thermostat:

Set adjustable heat anticipator at 0.4 Amps.

Low Voltage Rating (Terminals R&C):

Maximum cooling load of 40VA @ 24v. 60 Hz.

Continuous duty. W & C cycled through thermostat.

Safety Timing: 45 seconds

- TYPE 668-451 - Emerson Climate Technologies @ Emerson (PDF)

Testing

The following control checks should be made after each installation to insure that the controls are correctly wired and functioning properly.

1. Open the main line switch.

2. Adjust thermostat or operating control to call for heat.

3. Operate the manual reset button on top of control.

4. Make certain that high limit control is set at the correct temperature.

5. Open the hand valve in the oil line. The system is now ready for the following tests.

A. NORMAL CYCLE:

Close the line switch. The burner should start and continue to run normally. (If burner starts, establishing flame, but then locks out on safety, make “Flame Detector Check” at this time.)

B. SAFETY TIMING:

1. Let the burner run for about 5 minutes. Then remove one of Flame Detector leads from the “F” terminals. After a time period corresponding to the safety timing has elapsed, the control should lock out on safety, stopping the burner. 2. Open the line switch. 3. Replace Flame Detector lead removed in step 1. 4. Wait 3 minutes. Then operate the manual reset button on top of control.

C. HIGH LIMIT AND THERMOSTAT CHECK:

1. Close the line switch to start the burner.

2. Lower the setting of the high limit control to its lowest setting. This should stop the burner, unless furnace or boiler temperature is below the minimum setting of the high limit.

3. Return high limit control to its proper setting. Burner should restart.

4. With the burner running, turn thermostat to its lowest setting. This should stop the burner, unless actual room temperature is below the lowest setting of the thermostat. On systems supplying domestic hot water, burner will continue to run if low limit control is not satisfied.

5. Return thermostat to its proper setting.

D. FLAME DETECTOR CHECK: (This test is not required if the control performs as described in test A.)

If the burner starts but the control locks out (stopping the burner), check the flame detector as follows:

1. Open the line switch.

2. Connect one end of a wire jumper to one of the “F” terminals.

3. Start the burner by closing the line switch. As soon as the flame has been established, connect the other end of the wire jumper to the other “F” terminal. The control provides NO SAFETY PROTECTION with this jumper installed. DO NOT leave burner in this condition except for making this check. If the control still locks out with the jumper installed, the control should be replaced. If the control does not lock out, however, check the operation of the 956 flame detector as follows:

NOTE

! WARNING Possible Cause of Trouble

- Open circuit in Cell - Replace Cell (or Cell Assembly) of 956 Flame Detector. Do not disturb position of bracket or socket assembly.

- Flame detector improperly positioned - Locate flame detector according to the burner manufacturer’s specifications.

Documentation

- White-Rodgers 668-451 Installation Manual

- Reset Button Operation on Primary Controls for Oil Fired Heating Equipment

- Cad Cell Relay Switches on Oil Burners

- Tech specs, replacement parts

- Tech specs, replacement parts

Safety

- Oil Burner Puffbacks - an explosion of un-burned oil in the combustion chamber of an oil-fired boiler, furnace, or water heater.

See also

- Oil burner @ Wikipedia